Meyland Discharge Hopper

Unload bulk goods quickly and efficiently with minimal dust emissions

How do you unload dry bulk goods efficiently from ships with a minimal impact on the environment? That is a huge challenge for many port companies. The Discharge Hopper, a funnel-shaped hopper, is Meyland’s cost-efficient and ecological solution that is fully adaptable to your specific needs and port capacity.

Boost your productivity

Need to unload grain, iron ore, coal, bauxite, phosphates or maize? The Meyland Discharge Hopper is designed to unload almost every bulk material quickly into a truck or onto a conveyor belt. The robust hoppers can be set up on any quay and are resistant to inclement weather. With a flow capacity of up to 6000 tonnes per hour, depending on your grab crane, you will see your import capacities growing considerably whilst saving precious time. You can immediately continue processing your bulk goods or transport them to another location or storage area.

Reduce your impact on the environment

A large amount of dust is released when transhipping or stockpiling dry bulk goods.The dust particles raised pollute the air and water in the port, which is why governments all over the world impose measures on port companies to limit environmental pollution. The Meyland Discharge Hopper minimises dust emissions during unloading with a simple but effective anti-dust system. A small filter installation with Flip-Flaps cuts down the amount of billowing dust as well as limiting material wastage. That makes the Meyland Discharge Hopper an ecological solution for handling dry bulk goods.

Modular design: adjustable and extendible

Many different bulk goods are imported and exported at international ports every day. Every company, every type of bulk goods and every port have different characteristics and a wide range of needs in terms of safety, infrastructure and transport.

That is why we find it important here at Meyland to design our Discharge Hoppers to suit each customer’s requirements. Thanks to our modular design process, we keep lead time low, so that you can start using your hopper without delay.

We always start with a standard hopper design. Depending on your wishes, we make adjustments and add features until the Discharge Hopper perfectly fulfils all your needs.

Built locally to use internationally

Our experienced engineers and technicians design and build each Discharge Hopper entirely in Belgium to begin with. After a series of extensive tests, the hoppers are dismantled, ready for shipping to their final destination.

standaard module

materiaalspecificaties

grijpomvang

afmetingen vultrechter

vereisten stofbestrijding

lage of hoge opbouw

los & transportopties

Meyland Batchweger op maat

Minimal dust emissions

Various unloading options

High safety

Fixed or mobile

Robust design

Fully customised

Suitable for all ports

Powerful dust control

If you unload dry bulk goods into an ordinary hopper, you can hardly avoid problems with dust. The Meyland Discharge Hopper puts an end to that. Our hoppers are equipped with an effective anti-dust system.

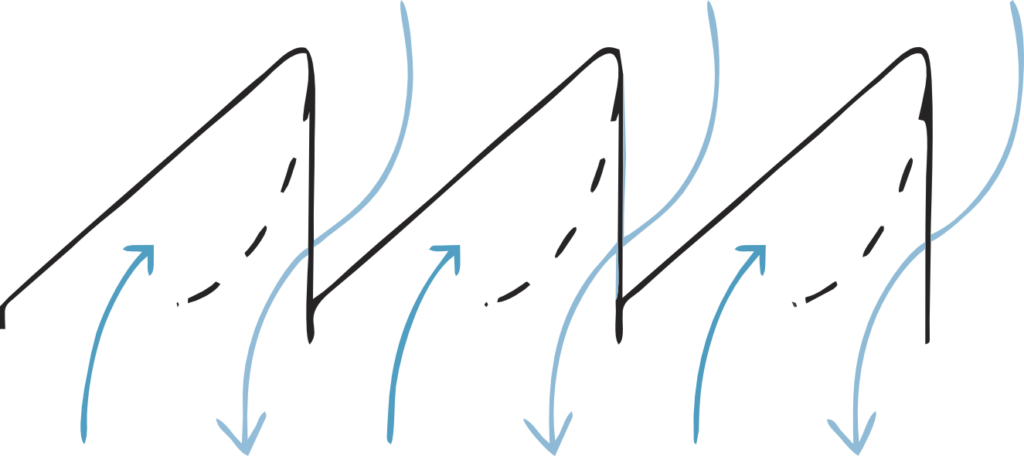

How does it work?

There is a grille in the hopper chute. We attach a powerful system underneath it with ‘Flip-Flaps’, vertical rubber flaps that keep the dust down.

The Flip-Flaps open to let the bulk goods flow through the chute, and close again to prevent air and dust being released from the chute.

As soon as the grab crane releases the bulk goods, they fall through the Flip-Flaps into the lowest part of the chute. That means that the air there starts to move and tries to escape.

That movement of air pushes the Flip-Flaps closed, automatically removing the dust through a dust extractor. Thanks to the Flip-Flaps, compact filters are sufficient.

That means you don’t need to invest in a complex anti-dust system.

lossen in vrachtwagen

lossen op transportband

Unloading options

Unloading to trucks

If your bulk goods need to be transported immediately from the port to a different location, it may be useful to unload them directly into a truck.

For this, we install a loading unit with an anti-dust system that simultaneously loads the contents of the chute into one or two trucks.

Unloading to a conveyor belt

Your bulk goods can also be directly unloaded from the Meyland Discharge Hopper onto a conveyor belt.

An adjustable unloading unit ensures that the bulk goods are released at the correct speed for uniform distribution over the conveyor belt.

Transport options

Can your hopper remain on the quay permanently? If so, a fixed Discharge Hopper is ideal. But what if you need a movable hopper, for example to free up space on the quay when it is not in use? In that case, a mobile Discharge Hopper is a better option

Installation on rails

The entire installation is put on steel rails that run parallel to the quay. Depending on your needs, you can operate the Hopper independently or as a single system with a crane.

Air tyres

Do you need more freedom of movement? If so, we will mount your hopper on hydraulically driven and rotatable air tyres.

maximale flexibiliteit

2- of 4- wielaandrijving

eigen stroomvoorziening mogelijk

wegen

breken

cloud

Extra options: weighing and breaking

Weighing

Do you like to keep control of the amount of material unloaded? If so, we will fit the Meyland Discharge Hopper with a calibrated weighing system. Do you want to know exactly how many tonnes of bulk goods are passing through your hopper at any given time? That is also possible with a flow weigher and even automatic data uploading to the cloud.

Breaking

Do you process materials that tend to clump together, blocking the unloading system? A double breaker in your Meyland Discharge Hopper deals with that problem.

Are you also looking for a way to boost your productivity and reduce your impact on the environment?

We look forward to discussing with you how a Meyland Discharge Hopper can help your company get ahead.